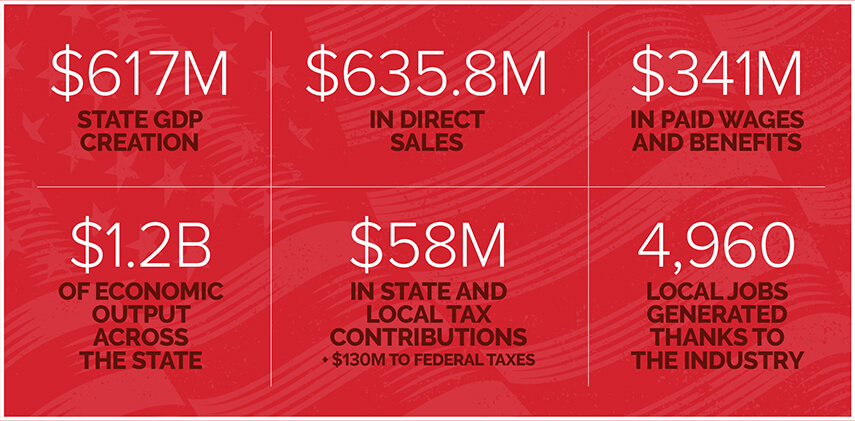

An independent analysis found that the reinforced concrete pipe industry generated the following impacts on the Texas economy in 2018:

The industry’s economic impact is characterized in three categories: direct impacts, indirect impacts and induced impacts.

Direct impacts refer to the economic activity resulting from the industry’s capital and operational outlays on items such as materials, labor, management, and consulting and technical services. For example, the increase in demand for cement is a direct impact.

Indirect impacts refer to the economic activity resulting when the recipients of direct impact activity then spend a portion of that revenue on goods and services from their own supply chain. For example, an indirect impact would be the additional workers hired and materials purchased by cement producers to meet the increased demand for cement.

Induced impacts refer to the economic activity resulting from the spending of income earned by employees within the “directly” and “indirectly” affected industries. The beneficiaries of this spending are primarily consumer-related businesses such as retail, restaurants and personal service businesses.

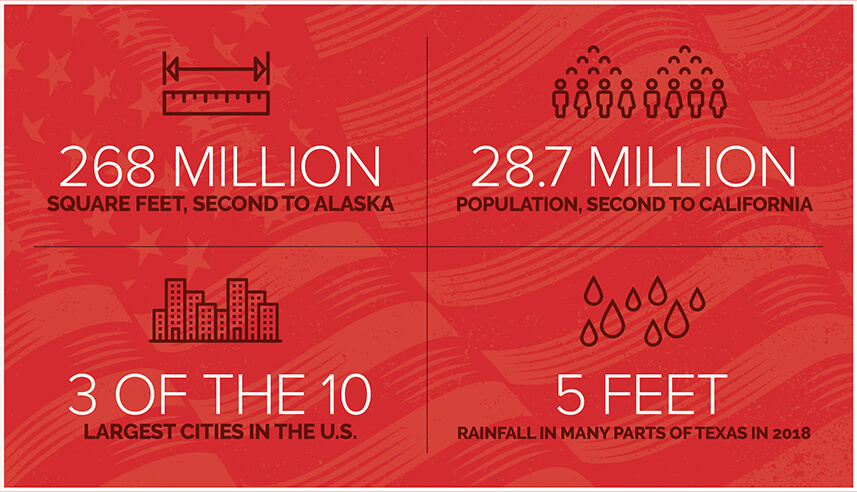

As the second largest state in the U.S. in terms of square mileage and population, Texas is home to three of the ten largest cities in the U.S. and three more of the top twenty largest cities. With increasing heavy rainfall in many parts of Texas, the state’s needs for piping infrastructure, particularly storm drainage, are significant.

With producers throughout Texas, the reinforced concrete pipe industry is more than ready to meet the demands of our state’s growing population. .

Manufactured by producing a cage of steel mesh, enclosing it in a form or mold and then pouring concrete around it, reinforced concrete pipe offers several distinct advantages:

The pipe chosen to meet the demands of storm water drainage must be strong and capable of withstanding the load placed by soil, roadway and cars. In the end, this cost is borne by the citizens of municipalities, making a low lifecycle cost highly desirable. Durability and long life are also important, because the process of replacing storm water drainage infrastructure can be disruptive to the public at large.

Reinforced concrete pipe is a product leader for storm drainage applications with a proven track record in terms of economic life, with many systems in service for as long as one hundred years.

Both corrugated galvanized pipe and HDPE plastic pipe rely on installation with adequate bedding to provide strength. This means that the installation must properly address bedding material, bedding width and compaction requirements at the sides of and above the pipe – or the pipe will not perform properly. On the other hand, on an installed basis, reinforced concrete pipe does not rely on bedding at the site to provide strength.

This matters because pipe failures in storm water applications have occurred because the support offered by the bedding has been inadequate to deal with changes in the landscape at the site, including extreme weather events.

Not only is reinforced concrete pipe a superior product for strength and durability and low lifecycle cost, the industry is a major factor in the prosperity of Texas with over $635.8 million in sales in 2018. The reinforced concrete pipe industry also contributes significantly to the broader state economy with these macroeconomic impacts: